Air Filter Neglect – Two Proven Ways to Kill a Turbo

In the past, we’ve discussed at length how the evolution of modern engines is impacting the way that drivers need to think about maintaining their vehicles. This conversation usually takes place in the context of small, low-displacement engines that get a major boost in power via turbocharger technology. If you’re unfamiliar, I recommend that you check out this recent post to see just how many turbocharged vehicles are already in operation and learn how saturated the market is projected to be in five years.

We know a lot about why proper lubricant and oil filter maintenance is important to any turbocharged vehicle, but are there any other filters critical to the optimum performance and longevity of a turbocharged engine? YES, absolutely. In fact, all of the VIO turbo statistics that we’ve previously shared are just as important when we’re talking about engine air filter maintenance.

To Explain Why, Some Turbocharger Education is in Order…

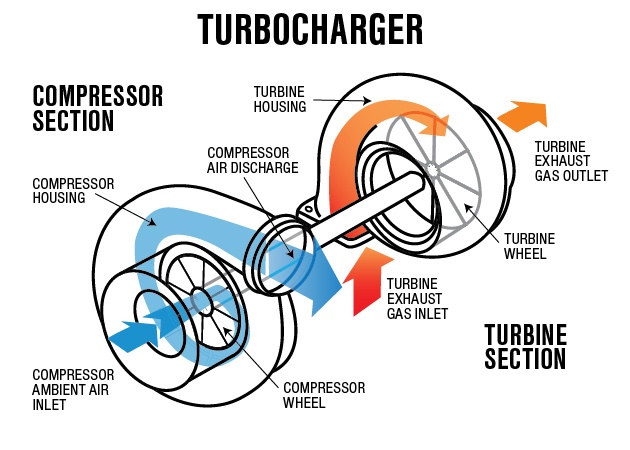

A turbocharger works similarly to the turbine of a jet engine. It’s made up of 2 main parts – the compressor side and the turbine side. The process begins when cool air enters the engine’s air intake, where the engine air filter lives, and then makes its way to the compressor. Inside the compressor is a fan that helps suck in that cool air. Once the air reaches the compressor, it is… compressed and heated up before being blown out past a heat exchanger, which cools it down before it enters the cylinder’s air intake. The extra oxygen in the cylinder helps burn fuel at an accelerated rate and when that happens, more energy is produced more rapidly – resulting in more power being sent to the wheels of the car through all components of the drivetrain. The process of producing this extra power creates a lot of extra waste gas, which has to go somewhere. The excess gas that’s produced is blown out through the exhaust outlet in the turbine, causing it to rotate at a high rate of speed. Because the fast-spinning turbine is connected to the same shaft that spins the compressor, the compressor also spins – in turn, sucking in additional cool, ambient from the air intake.

Hopefully, now that you know the basics of how a typical turbocharger setup works, it’s easier to understand why a healthy engine air filter is even more critical to the optimal operation of a turbocharged vehicle than a vehicle with a naturally aspirated engine. Neglecting the engine air filter in a turbocharged vehicle could result in catastrophic failure of the turbocharger system.

This failure could happen as a result of foreign object damage or extreme heat – both of which would likely involve a severely clogged engine air filter. That’s a component failure that no one wants to experience because often times it’s going to result in 4 figure repair costs. If we’re talking about a performance or high-end vehicle like some European luxury models, the repair cost could easily be 5 figures.

How a Clogged Engine Air Filter Could Result in Foreign Object Damage to a Turbocharger

Turbochargers Are Sophisticated, Yet Fragile – A Clean Engine Air Filter Will Help Make It Last

That’s not to say that turbochargers don’t take a beating. They absolutely do, but the conditions are so extreme that eventual failure is inevitable. Extreme exhaust heat is what powers the turbine side of the turbocharger, and over time, 2000° temps will take a toll. Prolonged exposure to that kind of heat will eventually kill anything, guaranteed. Considering the potential 4 or 5 figure repairs cost we mentioned earlier, we’d try to prevent the turbo from getting to that point prematurely. Well, one of the most common causes of excess heat generation is a clogged engine air filter. If the filter is really occluded, the compressor won’t be able to suck in enough cool ambient air, resulting in added heat that the turbocharger really doesn’t need. Regular maintenance of the engine air filter is a good way to stay within the recommended heat threshold to keep a turbocharger working well for as long as possible.

Procrastinating on Air Filter Maintenance is a BIG Mistake

CAFE regulations are set for 100% implementation by 2025 and by that time, 90% of vehicles on the market will be powered by a turbocharged engine. Turbochargers are here to stay and because of that, the way we care for vehicles has to change a little bit. Many people remain unaware of exactly what this change means for routine maintenance. With a naturally aspirated engine, it’s sometimes ok to procrastinate a little bit when it comes to some filter changes. Going a little bit over the drain interval for an oil filter or the recommended change interval for the air filter? Usually, no big deal and neither situation is a reason for lost sleep. That’s not necessarily the case with a turbocharged application. We’re talking about a sophisticated, critical engine component that’s also fragile because of the constant punishment it endures – And, to overlook any routine filter maintenance, even by a little bit, could be a costly mistake.

Tags: Oil Change, Oil Filter, Synthetic Oil, Turbo, Turbocharged, Turbochargers

Categories: Air Filters, FiltersShare this entry